What do Western Electric Company and potatoes have to do with Quality by Design (QbD)?

Dr. Joseph M, Juran coined the term “Quality by Design.” The term built on concepts introduced by his Western Electric Company colleagues Walter Shewhart, and Dr. W. Edward Deming: Shewhart introduced the use of statistics and measurements of process variations to evaluate process stability, while Dr. Deming proposed a systematic approach for continuous improvement that accounts for the human factors of quality.

Meanwhile, following World War II, the UK was looking for ways to improve the yield of potato crops. Researchers adopted the design of experiments (DOE) approach first outlined by Sir Ronald Fisher in the early 20th century. DOE significantly impacted agricultural science.

Today, DOE is a preferred method for implementing QbD initiatives.

QbD for the Pharmaceutical Industry

While the automotive and electronics industries were the first to embrace QbD, the pharmaceutical industry has followed suit. The US Food and Drugs Administration (FDA) officially introduced QbD to its current goods and manufacturing practices (cGMP) in 2002.

According to the FDA, QbD is a “systematic approach to pharmaceutical development and manufacturing.” It begins with predefined objectives and emphasizes product and process understanding, along with process control. The QbD approach is based on both sound science and quality risk management. For pharmaceutical manufacturers, the advantages of QbD go far beyond contributing to the attainment of the FDA’s “better, cheaper, safer” mandate:

- Improved yields: Drugs manufactured using QbD methodology are less prone to variations, so there are fewer design freezes and failed batches.

- Shorter time to market: Implementing QbD usually reduces time to market. In some cases, time has been cut in half.

- Potential regulatory flexibility: QbD facilitates post-approval changes for movements within an approved design space, while real-time release testing (RTRT) can lower analytical testing costs.

DOE helps characterize the interdependencies between tank design and process operating conditions. But it can also be expensive and time-consuming to perform in a lab. CFD modeling offers a cost-saving option that can also reduce the risk of scale-up and day-to-day operations. However the simulation time and computational resources required to explore the relationships between various process parameters can still be prohibitively expensive. Cloud-based simulation software has emerged as a cost-effective option for QbD-driven DOE initiatives.

Establishing the Design Space of a Sparged Bioreactor on Microsoft Azure

The scale-up of pharmaceutical laboratory mixers to a production tank is no trivial task. It requires a thorough understanding of complex turbulent and multiphase processes impacting oxygen mass transfer. The interplay between the geometric design of the tank and tank operating parameters are critical to achieving good mixing, especially at larger production scales.

Meanwhile various geometry and operating parameters influence oxygen mass transfer scale-up from lab scale to production scale. Understanding the effect of these parameters can lead to robust design and optimization of bioreactor processes.

The main objective of this case study was to understand the impact of agitation speed and gas flow rate on the gas holdup and mass transfer coefficient, two critical parameters that help process engineers understand mass transfer performance. The research team used the general-purpose CFD tool ANSYS Fluent for simulations. The simulation framework was developed and executed on Azure Cloud resources running the ANSYS Fluent UberCloud container. This solution provided a scalable platform for achieving sufficient accuracy while optimizing the solution time and resource utilization.

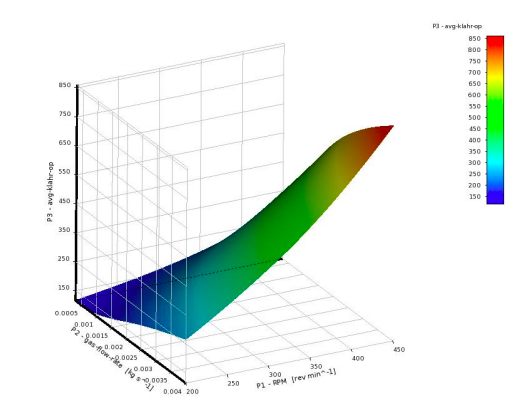

To study the design space of the bioreactor, the research team performed a DOE study to generate the response surface for the average mass transfer coefficient. They determined that agitation speed had a greater impact on the mass transfer coefficient than gas flow rate did. Even though increasing the agitation speed also increased the mass transfer coefficient, there was a limit to maximum speed; some processes involved mammalian cells that are sensitive to hydrodynamic shear. Therefore, studying the design space with several input parameters provided an opportunity to optimize the operating conditions to identify a safe operational range for the bioreactor.

|

| The figure above illustrates the response surface of average mass transfer coefficient versus gas flow rate and agitation speed. |

Results

Each simulation took less than one hour using 168 cores in the cloud. Mapping the entire design space, which took more than a week on the user’s workstation, required less than 24 hours. The research team identified multiple benefits:

- The HPC cloud computing environment with ANSYS Workbench with FLUENT and DesignXplorer streamlined the process of running a DOE with a drastically reduced process time

- Running the 10 design-point simulations and generating the response surface took only 24 hours of run time with 144 CPU cores. This means design engineers can quickly execute DOE analyses to study the scale-up behavior of their bioreactors.

- With the use of VNC controls in the web browser, HPC cloud access was very easy, with minimal installation of any prerequisite software. The enter user experience was similar to accessing a website through a browser.

- The UberCloud container helped smooth execution and provided easy access to server resources. The UberCloud environment, integrated with the Microsoft Azure platform, proved to be powerful because it facilitates running parallel UberCloud containers, with a dashboard in the Azure environment that helped in viewing system performance and usage.

The team concluded that Microsoft Azure with UberCloud HPC resources provided a very good fit for performing advanced computational experiments involving high technical challenges with complex geometries and multi-phase fluid flow interactions that would not typically be solved on a normal workstation. Pairing these technologies reducing the time required to establish a two-parameter design space for a bioreactor to a single day. Furthermore, the combination of Microsoft Azure, HPC Cloud resources, UberCloud containers and ANSYS Workbench with FLUENT helped to accelerate the simulation trials and also completed the project within the stipulated time frame.